Sustainable, climate-friendly – and a powerful petrol substitute

The most urgent challenge facing humanity requires swift and consistent action: Man-made climate change! The transport sector is still 95% based on fossil fuels. Electromobility is slowly gaining momentum, but it will be decades before a significant share is achieved. Sustainable ethanol (alcohol) made from renewable raw materials is already helping to reduce greenhouse gas emissions and will continue to be an important part of the solution in the future.

The British have been filling up with petrol E5 (up to 5% ethanol) for years. In September 2021, E10 (up to 10% ethanol) was introduced in the UK, as already done in many other European countries. By doubling the renewable ethanol content in the fuel a 750,000 tonne reduction in CO2 could be achieved in the UK every year. That is the equivalent of taking 350,000 cars of the road!

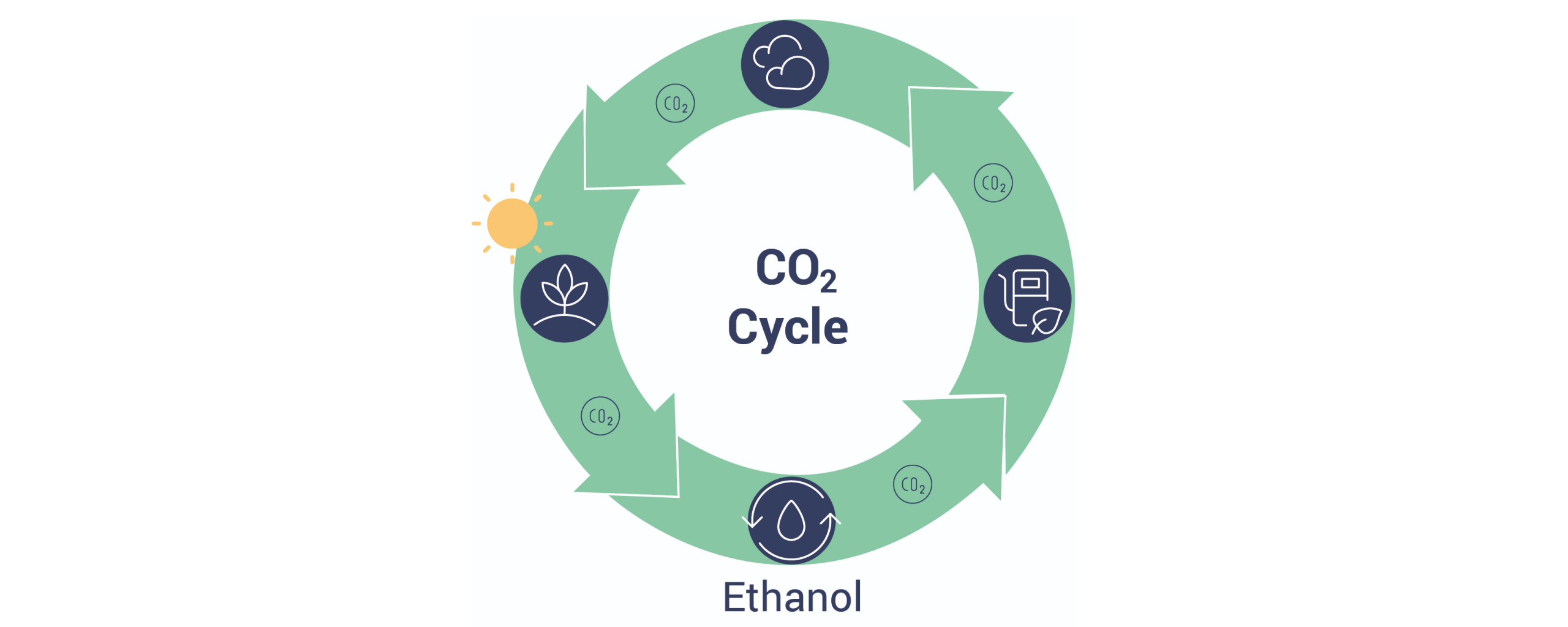

Thanks to highly efficient production plants, the CropEnergies Group reduces greenhouse gas emissions by over 70% compared to fossil fuels across the entire value chain. Ethanol only releases the CO2 that was previously bound by the plants during growth.

But the reduction in greenhouse gases is not the only advantage of European ethanol. It has a significantly higher octane rating than petrol, which means more power - and lower emissions of particulate matter and nitrogen oxides due to better combustion. In the future, higher blends of ethanol in fuel will be possible, and newer petrol engines are already approved for fuel with 20% ethanol (E20).

All the CO2 released during ethanol combustion was previously absorbed by the plants during their growth. With ethanol replacing fossil fuels, more fossil carbon which is responsible for climate change can stay in the ground. The dependence on oil-producing countries is reduced.

Our ethanol is produced by sourcing suitable biomass from British farmers, when economically viable, avoiding long transport distances wherever possible. We create jobs and added value in rural areas.

The raw materials used must not come from areas with high carbon stocks or high biodiversity.

Independent experts check the origin of the raw materials and their processing as well as the calculations of greenhouse gas savings at regular intervals in accordance with a state-approved certification system.

A special feature of ethanol production is the use of all resources. During production, only the starch or sugar content is required for the ethanol. The remaining components of the initial resources are processed into protein feed, liquefied CO2, gluten or other products.

Our quality assurance with modern process control technology and our own analysis laboratories starts with the raw materials used and only ends with the tank or tank trucks that are only used for ethanol.